Wear parts made of Tungsten Carbide and Ceramic

SCHELL is one of the professional suppliers of precision grinded and ready-to-install wearing parts made of tungsten carbide, PCD and technical ceramics. Only high-quality carbide grades designed for the application are used.

Tungsten Carbide Parts are used in industries such as instrumentation and apparatus engineering, textile machine construction, printing machine construction, electrical industry, mold and tool making, medical technology, plastics industry, decorative hard material parts.

Wear parts made of carbide

Production examples of solid carbide: stripping knives, trimming matrices, shearing tools, carbide support rails for centerless grinding, expansion mandrels, bending pins, bending blades, solid carbide bushes, drill bushings, wire cut nozzles, nozzles, foil knives, guides, rails, guide blocks, mica cutters, hot runner elements, carbide-machines, hollow tips, solid carbide knives, balls, punches, dies, tungsten carbide knives, machine knives, low pressure knives, top knives, plates, radial rings, round knives, stencils, cutting inserts, spindles, stamping drums, punching rings, punches, punches, punching rings , Hard metal wear parts, valve cone, etc ...

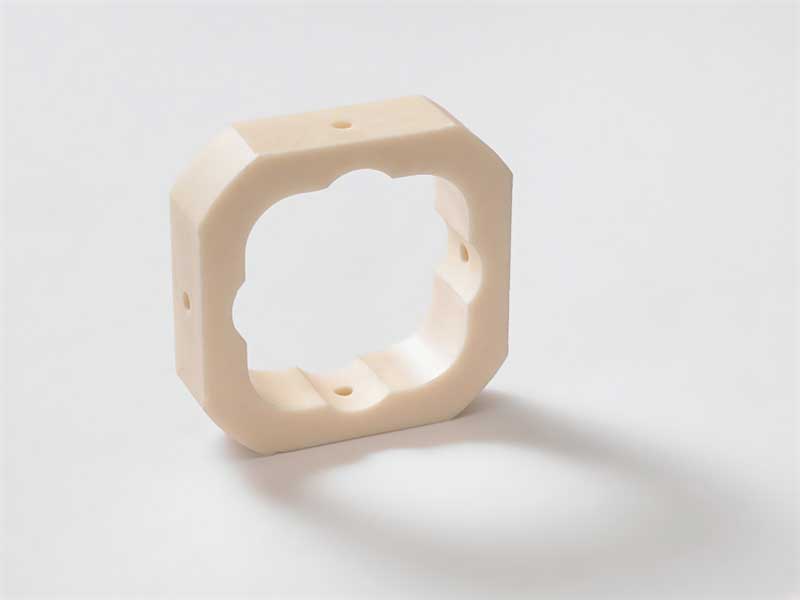

Wear parts made of technical ceramics:

SCHELL is a competent partner for wear parts made of silicon-carbide ceramics and alumina ceramics. Ceramic materials are generally formed at room temperature from a raw material consisting of ceramic powder, organic binder and liquid, and their typical material properties are obtained only during a sintering process at high temperatures. This is the big difference to many other material classes, especially the metals.

The actual engineering performance therefore lies in the precise design of the manufacturing process and in particular in the targeted influencing of the microstructures in the final sintering process.

Properties of technical ceramics are:

- Heat resistance up to above 1000 ° C

- electrically insulating (e.g., spark plugs)

- extremely high abrasion and wear resistance (for example sliding surfaces, nozzles for laser and water jet cutting, slides)

- high hardness (eg in ball bearings)

- Corrosion resistance (salt water, chemical applications)

- Good biocompatibility (e.g., in medical applications)

- low thermal expansion

- low density

- high mechanical strength, but combined with low fracture toughness

- Form stability (high specific stiffness or high modulus of elasticity)

- low or high thermal conductivity depending on type

- high electrical insulation capacity or semiconductor or piezoelectric properties (functional ceramics) depending on type

We look forward to your inquiry about our Tungsten Carbide Parts.

Call us too: 0049 7024 40898-0